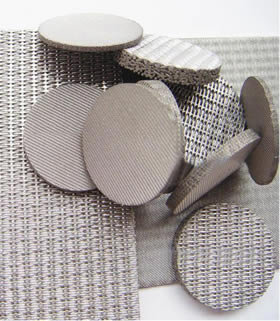

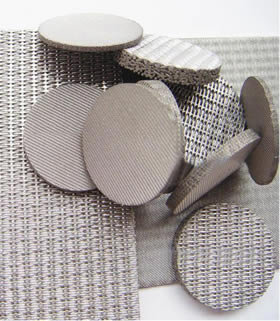

Sintered filter mesh has various shapes.

Sintered filter mesh is a kind of most widely used filtration material. It has 3 layers to 8 layers in total. The commonly is 5 layers. The material of sintered filter mesh can be stainless steel wire, monel wire, inconel and other wires. The materials are woven or perforated into meshes and then the meshes will be vacuum sintered into sintered filter mesh.

The five layers of sintered filter mesh are cover layer, filtration control layer, dispersion layer, support skeleton layer and skeleton layer. Sintered filter mesh can be filter discs, filter tube or other filter types.

Sintered filter mesh has various shapes.

Specifications

| Model | Nominal Filter Rating (um) | Structure Protective Layer + Control Layer + Dispersion Layer + Reinforce Layer + Reinforce Layer | Thickness (mm) | Air Permeability (L/min/cm2) | Bubble Pressure (mm H2O) | |

|---|---|---|---|---|---|---|

| RSM5-1 | 1 | 100 + 400 × 2800 + 100 + 12 × 64 + 64 × 12 | 1.7 | 1.81 | 360 - 600 | |

| RSM5-2 | 2 | 100 + 325 × 2300 + 100 + 12 × 64 + 64 × 12 | 1.7 | 2.35 | 300 - 590 | |

| RSM5-5 | 5 | 100 + 200 × 1400 + 100 + 12 × 64 + 64 × 12 | 1.7 | 2.42 | 260 - 550 | |

| RSM5-10 | 10 | 100 + 165 × 1400 + 100 + 12 × 64 + 64 × 12 | 1.7 | 3.00 | 220 - 500 | |

| RSM5-15 | 15 | 100 + 165 × 1200 + 100 + 12 × 64 + 64 × 12 | 1.7 | 3.41 | 200 - 480 | |

| RSM5-20 | 20 | 100 + 165 × 800 + 100 + 12 × 64 + 64 × 12 | 1.7 | 4.50 | 170 - 450 | |

| RSM5-25 | 25 | 100 + 165 × 600 + 100 + 12 × 64 + 64 × 12 | 1.7 | 6.12 | 150 - 410 | |

| RSM5-30 | 30 | 100 + 450 + 100 + 12 × 64 + 64 × 12 | 1.7 | 6.7 | 120 - 390 | |

| RSM5-40 | 40 | 100 + 325 + 100 + 12 × 64 + 64 × 12 | 1.7 | 6.86 | 100 - 350 | |

| RSM5-50 | 50 | 100 + 250 + 100 + 12 × 64 + 64 × 12 | 1.7 | 8.41 | 90 - 300 | |

| RSM5-75 | 75 | 100 + 200 + 100 + 12 × 64 + 64 × 12 | 1.7 | 8.7 | 80 - 250 | |

| RSM5-100 | 100 | 100 + 150 + 100 + 12 × 64 + 64 × 12 | 1.7 | 9.1 | 70 - 190 | |

| RSM7-150 | 150 | 50 + 100 + 50 + 30 + 30 + 100 + 50 | 2.0 | 25.00 | 50 - 150 | |

| RSM7-200 | 200 | 40 + 80 + 40 + 20 + 40 + 80 + 40 | 2.0 | 26.00 | 50 - 150 | |

| Weight (kg/m2) | 5-layer sintered wire mesh(8.4) 6-layer sintered wire mesh (14.4) | |||||

| Porosity (%) | 40% | |||||

Woven sintered filter mesh.

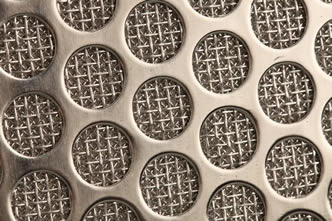

Perforated sintered filter mesh.

Sintered filter disc.

Sintered filter tube.

Sintered filter element.

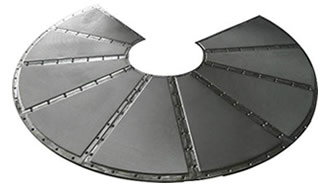

Sintered filter plate.

Features

Applications

The sintered filter mesh is widely used as the filtration material for liquid, gas and other media in various fields.

Package

Sintered filter mesh in carton package.

Sintered filter mesh in wooden box package.