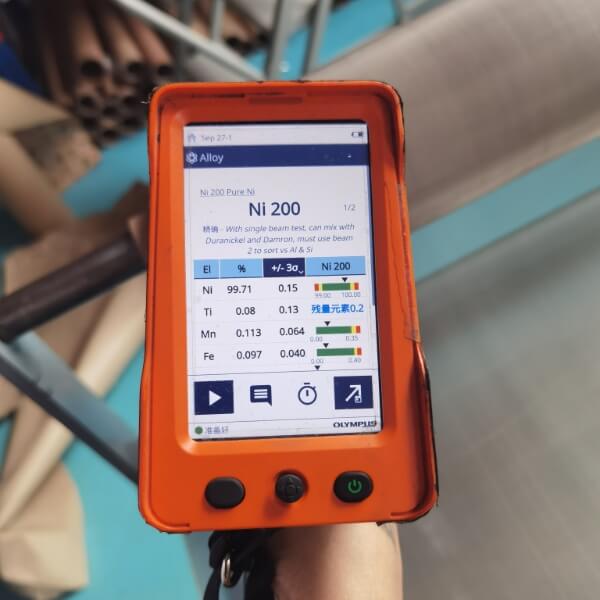

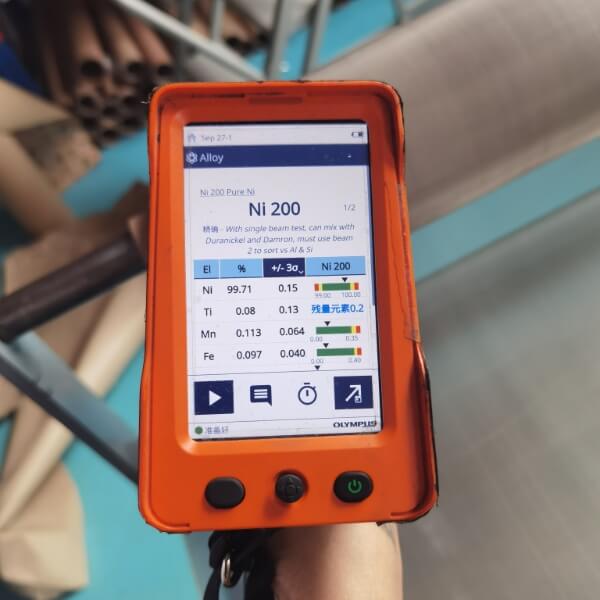

Nickel woven wire mesh chemical composition measurement.

Nickel mesh electrolysis is a promising method for hydrogen production due to its simplicity and cost-effectiveness. The process involves using a nickel mesh as the anode and a cathode made of a different material, such as stainless steel. An electrolyte solution is used to facilitate ion flow between the anode and cathode. This solution can be made from a variety of substances, including sodium hydroxide, potassium hydroxide, or even seawater.

When an electric current is applied to the system, water molecules are split into hydrogen and oxygen gas. Hydrogen gas is collected as the product of the reaction, while oxygen gas is released into the atmosphere. The efficiency of this process can be increased by optimizing electrode design, electrolyte concentration, and current density.

One advantage of nickel mesh electrolysis is that it can be easily scaled up for large-scale hydrogen production. Additionally, nickel is a relatively abundant and inexpensive metal, making it an attractive choice for use in this process. However, there are also some challenges associated with this method, such as nickel corrosion potential and the need to carefully manage the electrolyte solution.

Product Display

Nickel woven wire mesh chemical composition measurement.

Mesh count of nickel woven wire mesh measurement.

Nickel woven wire mesh width measurement.

Nickel woven wire mesh length measurement.