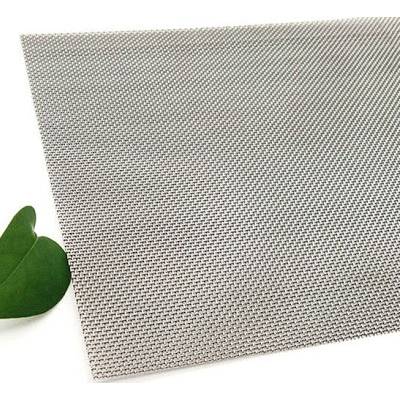

Woven Wire Mesh - Ideal for Filtering and Sieving.

Established in 2000, we are keen into manufacturing and exporting woven wire mesh suit for the international market and requirements of customers.

As a specialized manufacture of woven wire mesh, we can supply a broad selection for you. So that you can get a complete information about it and choose the perfect one for you.

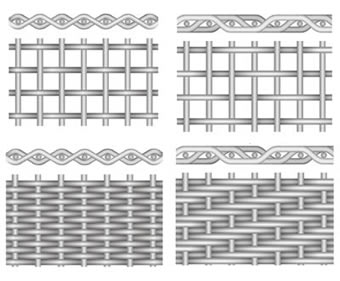

Woven wire mesh weaving type

Woven wire mesh has various weaving types.

The main production of woven wire mesh is weaving. Weaving type has various types, including the plain weave, twill weave, dutch weave and reverse dutch weave.

Plain weave woven wire mesh and twill weave woven wire mesh are mainly used for screening such as the window screen, insect screen and other applications.

Dutch weave woven wire mesh and reverse dutch woven wire mesh have different wire diameter of weft wire and warp wire, which finer wire can supply accurate and quick filtration performance and the coarser wire can supply the high tensile strength. The dutch woven wire mesh and reverse dutch woven wire mesh are widely used as filtration materials in the chemical, petroleum and other industries.

Pure material woven wire mesh

Pure material woven wire mesh refers to the purity of material can achieve 90% to 100%.

Major pure material woven wire meshes are copper woven wire mesh, nickel woven wire mesh, titanium woven wire mesh, silver woven wire mesh and black woven wire mesh.

Copper woven wire mesh owns 99.8% purity, which has outstanding shielding performance. The copper woven wire mesh is widely used for shielding interference and insulating noise.

Purity of nickel woven wire mesh is not less than 99%. It can resist to various chemicals and has excellent electrical and thermal conductivity.

Titanium woven wire mesh is corrosion resistance and nontoxic. It is widely used in the surgical operation for skull repair and reconstruction.

Stainless steel wire woven mesh with plain weave, twill weave, dutch weave, is suitable for security window screen, high precision filter elements, and used as printing mesh.

Alloy material woven wire mesh

Alloy material is combination of two or three chemical elements. Alloy woven wire mesh can suit for more applications than the pure material woven wire mesh. The main alloy material woven wire mesh are including copper-based woven wire mesh, nickel-based woven wire mesh and FeCrAl woven wire mesh.

Copper-based woven wire mesh is consist of brass woven wire mesh and phosphorous bronze woven wire mesh, which have different colors and features. They are all used in the papermaking and used as window screen or insect screen.

Nickel-based woven wire mesh can be divided into nichrome woven wire mesh, hastelloy woven wire mesh, inconel woven wire mesh and monel woven wire mesh. They are mainly used as filtration materials in chemical, petroleum, pharmacy, oil, aerospace and other fields.

FeCrAl woven wire mesh is the alloy of iron, chromium and aluminum. It is temperature and oxidation resistance, which is widely used in the gas and infrared burners.

Woven wire mesh application

Woven wire mesh has a wide range of applications.

Woven wire mesh with various materials and weaving types has a wide range of applications, which the most common is filtration. Detail applications are in the below.

- Industrial filtration. Industrial filtration need accurate and effective filtration. We can supply the filter discs and sintered filter mesh for high efficiency and fine filtering.

- Food filtration. The woven wire kitchenware has various types for food filtering and sieving, including water, oil and powder.

- Hops and hot breaks filtration. The bazooka screen is mainly used in the kettles, tuns and other containers to filter hops and hot breaks.

- Shielding. The copper woven wire mesh is used for shielding interference and RMI.

- Heating and warming.

- Protecting. Tobacco pipe filters are mainly used for protecting.

- Prevent tobaccos from entering mouth and protect safe of smokers.

- Prevent pipe from being burn by the fire and protect the pipe.

- Decorating. The phosphorous bronze woven wire mesh has smooth and beautiful surface, which can be installed indoors and outdoors for decoration.

Stainless steel wire woven mesh cloth with plain, twill, dutch weave, is suitable for security window screen, and high precision filter elements.

We can supply special alloy woven wire mesh in different chemical and physical properties for your filtering and screening in specific environments.

Blackened stainless steel shielding mesh has excellent shielding effectiveness and high transparency to be used in military, medical and mechanical industries.

Blackened stainless steel or copper mesh supplies excellent EMI shielding performance and high transparency for screens, control panels and windows.